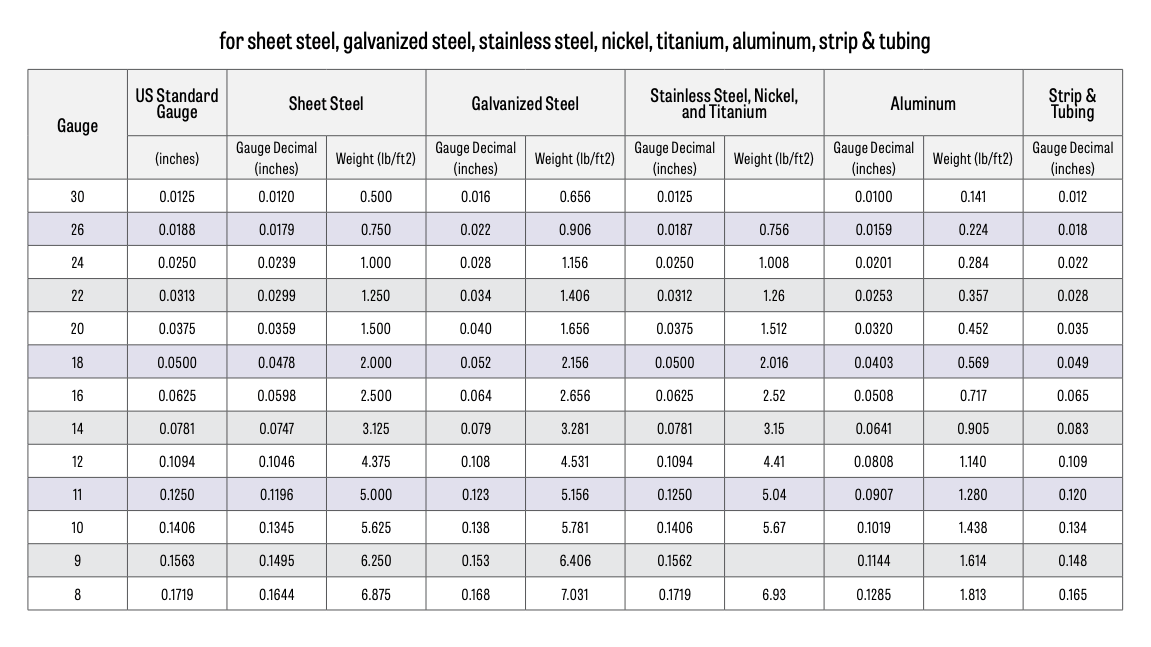

Whether calculating gauges for cold rolled, hot rolled, and coated materials, looking for sheet metal or coil measurements, or just looking for unit conversion to inches and pounds, Unravel does the work for you. If you’re looking for an even simpler solution to understanding the correct gauge, weight, width, and measurement conversions of any steel product, use our steel calculator Unravel. Follow the chart for the exact numbers you need. But, those numbers do not give you specific dimensional values. The inverse is also true, as the gauge number gets lower, the thicker the steel gets. The general rule across all gauge charts is the larger the number, the thinner the steel. Meaning coated steel gauges like galvanized are vastly different from uncoated steel like hot rolled and cold rolled gauges. The gage sizes are specified by numbers and the following. This is known as the Manufacturers Standard. The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a 'gauge' (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number increases, the material thickness decreases.

Sheet metal thickness gauges for steel are based on a weight of 41.82 pounds per square foot per inch of thickness. As the gauge number increases, the material thickness decreases. Gauges range from 3-31, each has a specific thickness assigned to it for the material based upon its weight. A sheet metal gauge (sometimes spelled 'gage') indicates the standard thickness of sheet metal for a specific material. When looking at a gauge chart, the key to understanding it, including our cold rolled chart, is to look at the number. The British iron wire industry adopted metal gauges over other traditional units like inches as the primary unit of measurement, and thus it’s become the standard for the steel industry, being used across sheet metals. That’s due to there being no universal thickness measurement for metal during the 19th century. Gauges are different from other measurement units such as inches or centimeters.

Now that you have the right chart, it’s time to understand how it’s meas ured. ASTM A240 Grade 304 Sheet is austenitic stainless steel stainless sheet and comes in many sizes, thickness and finishes. So, in this case, you’ll need the Cold Rolled Gauge Chart. You must use the specific gauge chart for each material to learn the right thickness.

It is essential to keep a copy of the gauge Chart handy when you design any part. For example, the 16 gauge stainless steel thickness is 1.60 mm, whereas the 16 gauge aluminum thickness is 1.29 mm. The equivalent thicknesses differ for each gauge number. One point must be noted that the thickness will be different for different materials for the same gauge. Standard gauge numbers and sizes were developed based on the weight of the sheet for a given material and coating. Meaning coated steel gauges like galvanized are vastly different from uncoated steel like hot rolled and cold rolled gauges. The first and most important rule of reading and understanding a steel gauge chart is using the right one.

0 kommentar(er)

0 kommentar(er)